Testing solar panels is crucial for ensuring safety, maximising energy output, and protecting your investment. This guide covers everything from fundamental checks to advanced diagnostics, providing a comprehensive overview for technicians, asset managers, and system owners. Proper testing helps diagnose issues like degradation, soiling, and electrical faults, and is essential for commissioning new systems and performing ongoing maintenance.

Essential Safety Precautions

Before conducting any tests, safety is paramount. Unlike AC systems, a solar array cannot be completely de-energised as long as there is daylight. Always assume the system is live and take the following precautions:

- High DC Voltage Risk: Be aware of the significant electric shock hazard from high DC voltages.

- Personal Protective Equipment (PPE): Where necessary, use properly rated insulated gloves, eye protection, and insulated tools.

- Lockout/Tagout (LOTO): Follow correct LOTO procedures for inverters and DC disconnects before working on the system.

Standard Solar Panel Testing (The Fundamentals)

These fundamental tests are the first step in assessing panel and array health.

Open-Circuit Voltage (Voc)

What it is: The maximum voltage (V) a panel or string can produce with no load connected. A low Voc can indicate a faulty panel or connection issue. Use a multimeter set to DC volts to measure between the positive and negative connectors and compare the reading to the manufacturer's data sheet.

Short-Circuit Current (Isc)

What it is: The maximum current (A) a panel produces when its terminals are shorted together. This test, performed with a DC clamp meter, helps assess cell performance. Low Isc can indicate soiling, shading, or cell degradation.

Solar Irradiance Measurement

What it is: The amount of solar energy received, measured in Watts per square meter (W/m²). Since panel output is directly tied to sunlight, you must measure irradiance with a solar meter to know if your panels are performing as expected under the current conditions.

Array Safety & Integrity Tests

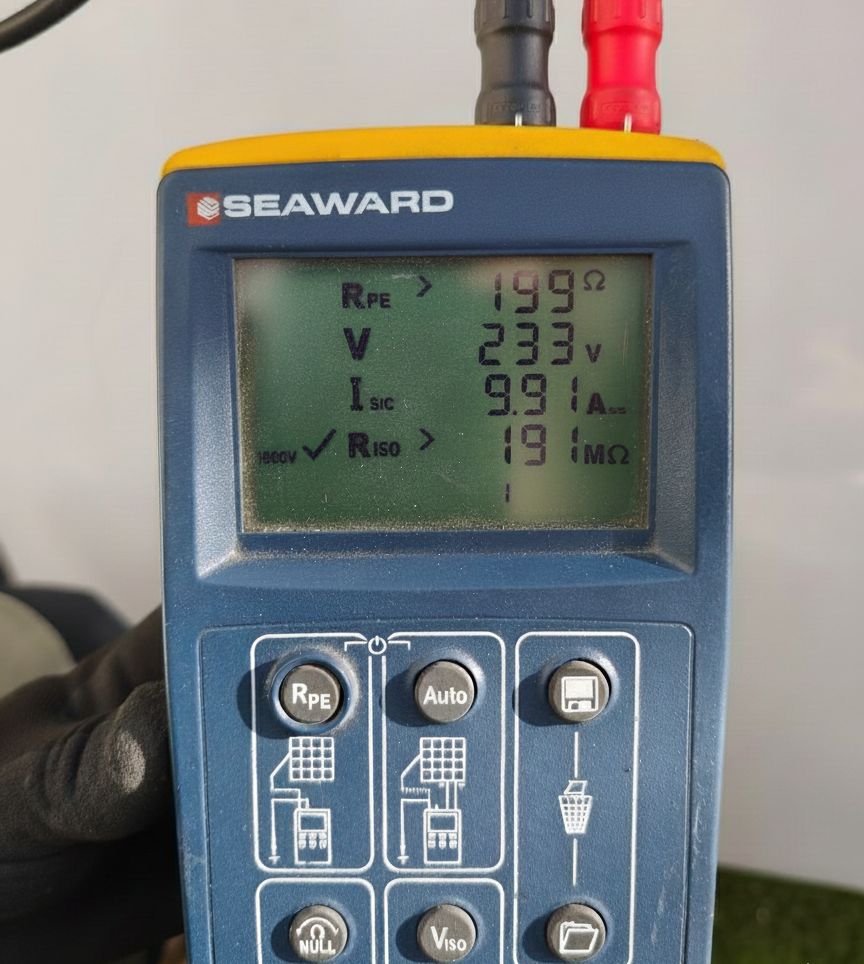

Array Insulation Resistance (IR)

This is a critical safety test to ensure there are no current leaks between the conductors and the earth ground, measured in Megaohms (MΩ). A low value indicates a fault that could lead to fire or shock hazards. The test is performed with an insulation resistance tester (megohmmeter) at a specific Test Voltage and checks:

- Positive to Earth: Resistance between the positive conductor and earth.

- Negative to Earth: Resistance between the negative conductor and earth.

Earth Continuity (Ground Bond)

This test verifies that all metallic components (panel frames, mounting rack) have a solid, low-resistance connection to the main earth ground, ensuring faults are safely directed away.

Advanced Performance Diagnostics

I-V Curve Tracing

I-V curve tracing is the most powerful electrical test for solar arrays. Instead of just measuring two points (Voc and Isc), it plots the entire current-voltage relationship of a string. This provides a complete performance picture and is the definitive tool for diagnosing complex issues like module mismatch, degradation, and shading effects by comparing the live curve shape to the manufacturer's specification.

Advanced Imaging & Specialised Diagnostics

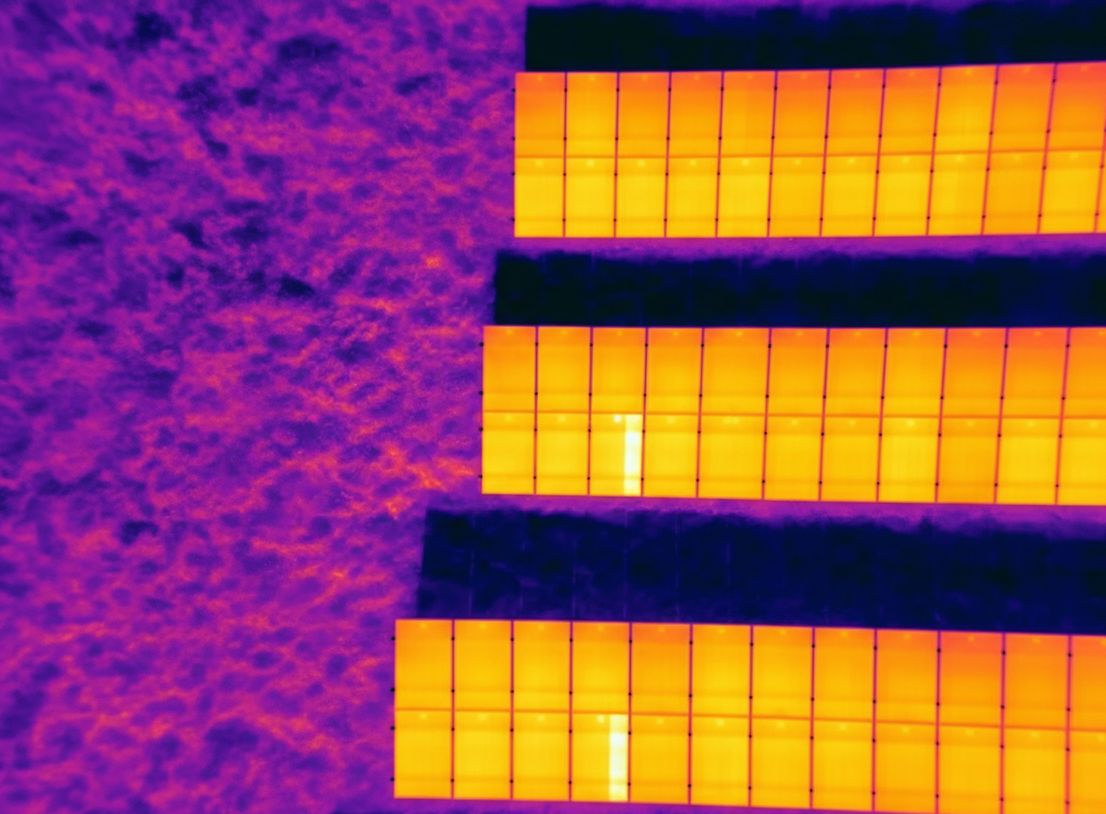

Thermal Imaging (Thermography)

Using an infrared camera, thermography quickly identifies temperature anomalies across an array. Hot spots often indicate problems like faulty bypass diodes, internal short circuits, or high-resistance connections that are invisible to the naked eye.

Electroluminescence (EL) Testing

Often called an "X-ray for solar panels," EL testing is a high-resolution imaging technique that reveals cell-level defects. By passing a current through a panel in a dark environment, it can identify microcracks, broken interconnects, and other hidden damage that impacts long-term performance and reliability.

About the Author

This guide was written by the engineering team at SMC Energy. As Chartered Engineers with deep expertise in solar diagnostics and performance optimisation, we are committed to providing clear, accurate information for the renewable energy industry. Contact us for expert advice on your project.